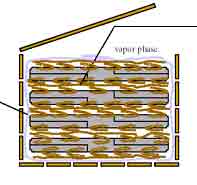

VCI PaperInterleave

VCI PaperInterleaveThe packaging design above protects metal parts from rust and corrosion. A VCI, plain poly or other barrier bag is used to contain the VCI Vapor Corrosion Inhibitors emitting from the VCI paper interleave. VCI paper interleave distributes VCI corrosion protection in the vapor and the contact phase throughout the package. Corrosion Protection Packaging Design Courtesy of Daubert VCI Inc.

Paper as a packaging material has its own unique advantages:

Daubert VCI papers come in a variety of grades. Larger or irregular shaped products should be protected with heavier grades of paper, while smaller parts can use lighter basis weights. Several Daubert VCI products feature special substrates that combine corrosion protection with barrier packaging. Barrier coated papers and films protect against moisture and grease; laminated grades afford heavy duty protection against the environment.

Daubert VCI papers are available in standard 36" or 48" rolls, and widths up to 120". Papers can be converted into bags, envelopes, wrappers for individual parts, shrouds for large pieces or stacks of parts, covers and liners.

Daubert VCI has several weights of kraft, plain or barrier coated papers to protect against moisture and grease. Laminated grades are available with polyethylene for heavy duty protection against the environment as well.

Daubert VCI can custom-print paper with your logo for easy identification to your customers. Your logo, instructions or message appears in crisp, clear detail.

| Corrosion Protection Home | Online VCI Paper Store | VCI Paper | Silver Saver Paper | Alumitex Paper | Coppertex VCI Paper | VPI Paper Explained |

| Packaging Design | HD VCI Paper for Ferrous Metals | Protec VCI Paper for Ferrous | Military Grade VCI Paper | Versil Pak | [Military Specification Products] |